It’s not every day that you come across a piece of industrial hardware with its own ancient Roman goddess. A seemingly simple component that has been helping us hold everything together and running smoothly for over 3,600 years. A mechanism that plays a pivotal role, pun intended, in the functionality of virtually anything that opens and closes and beyond.

The hinge. The first evidence of its use dates back to approximately 1600 B.C., supporting wooden doors pivoting from stone sockets in Hattusa, modern-day Turkey. The Romans later refined the design, incorporating a more advanced linking system into their large public structures. They also had a goddess of the hinge named Cardea.

What Are Hinges Used for?

These mechanisms connect two objects and enable them to rotate around a fixed axis while preventing movement in other directions. They are also used as load-bearing and structural support elements. You can find them everywhere, from doors and enclosures to furniture, jewellery, and electronics.

In an industrial context, these mechanical components have become indispensable parts of machinery, equipment, and infrastructure, built to withstand extreme loads, heavy-duty use, and harsh environments.

How Many Types of Hinges Are There?

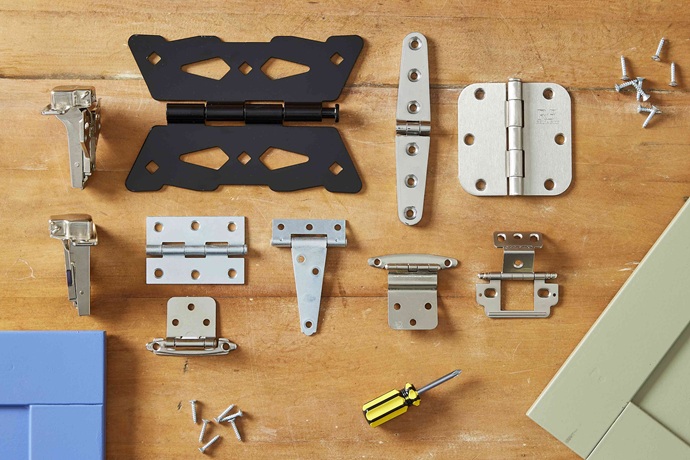

More than you’d imagine. Many factors contributed to their evolution and diversification, from industrialisation and wars to technological advancement. Nowadays, when shopping for hinges Australia-wide, you’ll come across quite an extensive variety. From standard butt-style to weld-on and more, here are some of the options you’d typically find in hardware supply stores.

Butt-Style

Used on doors, cabinets, lids, gates, and more, this classic and versatile joint features a curled barrel and two identical wings. One wing attaches to the moving part, i.e., the door, and the other one attaches to the fixed structure, allowing for movement on a fixed axis. These are available in various materials, including nylon and stainless steel, as well as different finishes to suit your needs and preferences.

Continuous

Also known as piano-style, this type runs the full length of a panel for even weight distribution. Available in stainless steel, galvanised steel, and aluminium, these components are typically employed in industrial enclosures, heavy-duty doors, machinery access panels, and truck compartments.

Concealed

As the name suggests, these are hidden from view for a cleaner look or tamper resistance. You can use them to ensure a seamless finish and functionality for cabinets, doors, and other applications.

Strap (Weld On)

Engineered for strength and durability, this type has a long, sturdy body that provides extra support for heavy doors and gates. They are permanently welded onto structures where high load-bearing capacity is essential.

Strap (Bolt On)

This type offers the same strength and durability as the previous one without the need for welding. A great solution for gates, barn doors, trailers, and other structures.

Flap

Usually found on toolboxes and industrial storage compartments, these mechanisms provide stability and flexibility for folding panels and access covers.

How to Choose the Right Ones for the Job?

The above is far from a definitive list. There is also industry-specific hardware for use in truck bodies, gates, tailboards, rear doors, etc. And that’s without going into the different materials and finishes, including but not limited to:

- Stainless Steel – Strong, durable, and highly corrosion-resistant, used in heavy-duty applications, marine, and outdoor environments.

- Brass – Corrosion and wear-resistant.

- Zinc-Annealed – Rust-resistant, suitable for general industrial use.

- Aluminium – Lightweight and strong, used in aerospace and transport.

- Nickel Plate – Durable and protected from moisture and oxidation with a sleek, polished finish, common in applications where aesthetics are of concern.

- Galvanised Steel – Rust-protected, ideal for construction and high-moisture areas.

There’s no scenario where unhinged is a good thing. Whether it’s a squeaky cabinet door, a malfunctioning machine panel, or a detached e-mail attachment, things tend to go south when these components aren’t doing their job.

That’s why, whether you’re choosing door hinges for your home or building a large cabinet, selecting the right type for your application is critical. Understanding load capacity, material durability, and movement requirements is vital to ensure a secure hold, trouble-free functionality, and lasting performance. If you’re unsure, consulting a professional can save you time, money, and potential headaches down the line.

When to Replace Them?

A worn, damaged, or faulty hinge can be anything from a minor nuisance to a potential disaster waiting to happen, especially when it comes to industrial applications.

Regular inspection can help you catch early signs of wear, like rust, cracks, or misalignment. Keeping hinges properly lubricated with industrial grease reduces friction and extends their lifespan. If you notice stiffness, noise, or excessive play even after cleaning and lubrication, it may be time for a replacement.

Where to Buy Hinges in Australia?

You can shop online or in-store, depending on your needs and preferences. Some suppliers offer both options for added convenience. No matter how you shop, pick a reliable supplier. They should offer high-quality products backed by industry certifications and strong customer reviews. This will help ensure durability and performance.