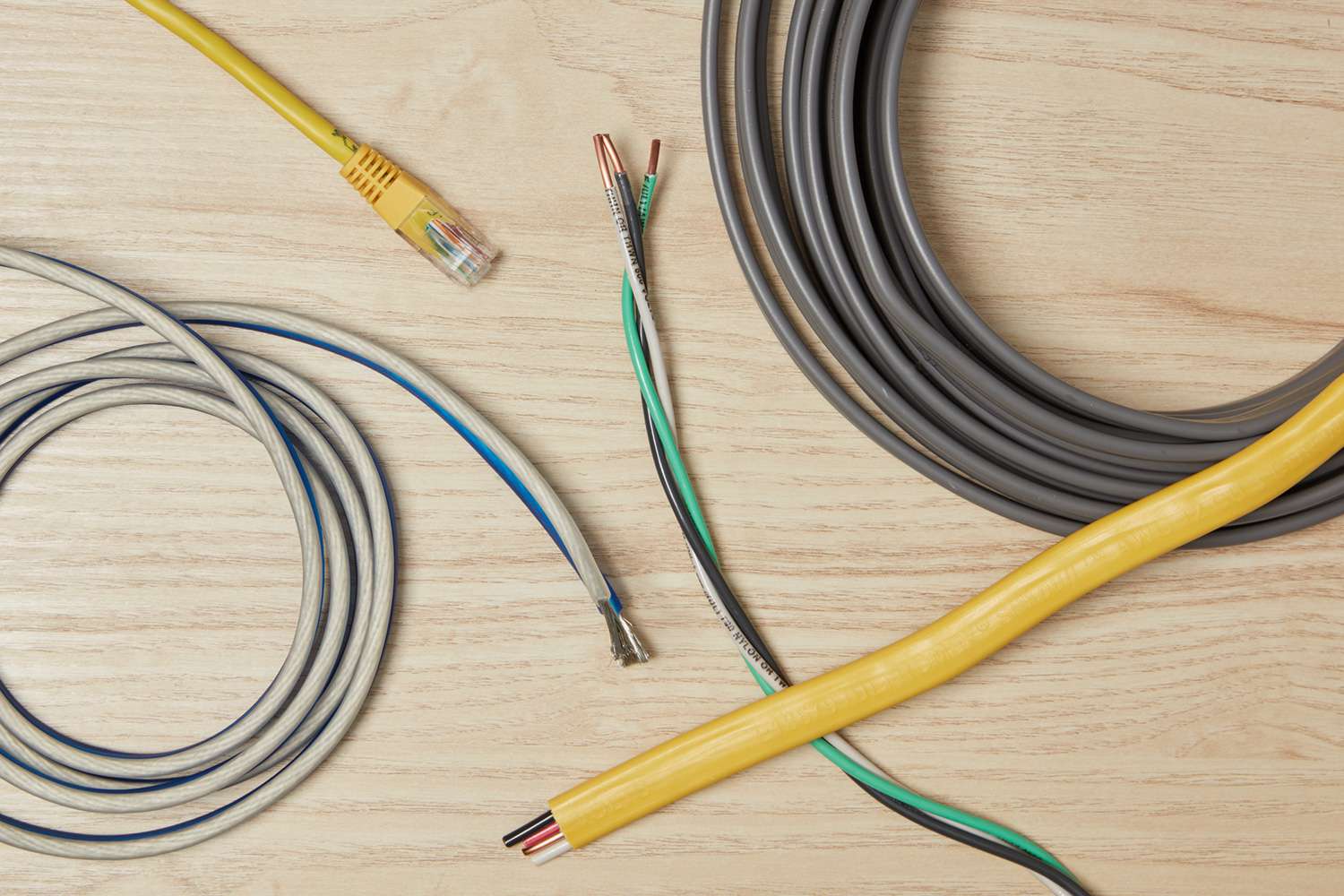

Cables and wires come in hundreds of different types and are used in a multitude of different fields. When we think of cables, it’s normally the fixed wiring running in walls or ceilings terminating in sockets and flex cables that connect appliances and devices to said sockets. These are referred to as power cables. Similar cables are used in industrial complexes to power large machinery. These though differ in some important ways as I’ll describe below.

The same settings have an abundant use of control and instrumentation cables and wires. Next, are lighting cables used to connect lights and switches. There are also communication or network cables, used to transfer signals, such as the fibre optic cable connecting homes to the NBN. These are just some of the types of wires and cables used, hence when shopping you’ll need to know exactly what you’re looking for.

Wires vs Cables – Know the Difference

Wires and cables refer to two different things. An electrical wire is a type of conductor, or a material used to conduct electricity. This is often made of aluminium or copper and can be bare or sheathed. Wires can also be of solid or stranded design. Cables, on the other hand, consist of two or more bare or sheathed wires encased in an insulated jacket. A typical power cable for household use, such as a twin and earth electrical cable, will consist of 3 wires – a brown active wire that carries electrical power from the mains supply and metering box to sockets, switches and hardwired appliances (like ovens); a blue neutral wire that redirects current back to the power source, and a green or yellow (or green/yellow) Earth wire that directs electricity away from appliances and sockets and into the ground in the case of electrical faults. The colour coding for the different types of wires was revised in 2018 and is known as the Australian Wiring Rules. This is to ensure that wires can be easily distinguished from each other.

Low-Voltage vs. High-Voltage Cables

Cables are sold with different voltage ratings. Low voltage cables can stand up to 750 volts and this is what’s usually found in single-phase residential or commercial power supply. Cables rated for up to 1000V are commonly found in factories, mines, manufacturing facilities, and any setting needing a consistent power supply. These are commonly three-phase cables, consisting of 5 separate wires- three active wires (coloured brown, black and white or grey), a blue neutral and a green and yellow Earth wire. A medium voltage electrical cable is one used in power and grid distribution, connecting power substations and transformers. These are rated for up to 36 kilovolts. And cables used to transfer power from generating plants to substations are referred to as high-voltage cables and have the highest voltage rating.

The Anatomy of a Cable

Cables consist of one or more wires or conductors, but also other parts that ensure the wires are protected from the elements and outside factors. This is to ensure that the power supply is consistent and that the cable lasts. Individual wires channel the flow of electricity, the insulation covering them contains the flow within the wire, (optional) protective auxiliary elements cocoon the separate wires, while the whole assembly is enveloped in the outer sheathing.

Wires can be made of a single solid core (and used in direct connections), or in multiple finer strands, and this is preferred in cables that need to be flexible. Here materials differ. Copper is the most common conductor found in wires, but where the highest conductivity is needed, silver is used, and where costs are a concern, aluminium.

The insulation is also of different types. Thermoplastic PVC insulation is the most widespread in low-voltage cabling, while heat and impact-resistant thermoset cables with insulation made of materials like rubber, silicone or modified polymers are common in harsher industrial environments. The insulation can then be protected with metal shields. Screens help to reduce outside interference, while armour resists mechanical impact. The metals often used here are aluminium and steel. Lastly, the outer sheathing protects against moisture, temperature extremes, and other factors and is often in the same materials as the insulation.

Power and Lighting Cables

These is the most common types of electrical cable sold. And they can be single or three-phase. The above-mentioned twin (core) and earth cables have an insulated neutral and live wire, and a bare solid earth wire.

Three core flex cables are found in extension cords and appliances and connect to the socket. They have a colour-coded and insulated live, neutral and earth wire, and PVC outer sheathing.

Twin core cables are used to connect smaller and less powerful appliances or devices and miss out on the earth wire, but the neutral and active wires are insulated and retain the PVC sheathing.

Three-phase cables consist of three active wires, a neutral and a grounding wire. Each is colour-coded and insulated, but here there is also the addition of steel or aluminium mesh or plating and the usual PVC outer.

Cables used to power lights usually come in two types. Two core flat cables connect a single switch, while three core and Earth cables are designed to power two-way light switches, like those found in staircases or larger rooms with separate switches near each door.

What to Look for

When selecting power cables, besides using the right type for the application, you need to pay attention to the gauge or thickness of the cable. This is to ensure that there is minimal electrical resistance in the conductors. To help in this respect, the outer sheathing is differently coloured. General purpose cabling rated for lower current (up to 15 amps and what is used in house wiring) is often white in colour, and with a conductor thickness of between 1.5 to 2.5mm2.