Need a versatile fastener to secure shelves, hold brackets, or support rails to brick, block, or concrete? Consider using a sleeve anchor. These are versatile expansion anchors ideal for medium-duty applications where durability and high holding strength are called for.

What are Sleeve Anchors?

Sleeve anchors are a type of expansion anchor used in masonry of all sorts. They expand into the substrate when tightened. And this can be all types of concrete, concrete block, solid or hollow brick, mortar, and stone. The result is a permanent anchor that can easily hold timber or metal fixtures weighing in excess of 100 kilos.

What are Dynabolts?

Dynabolts are the Aussie take on sleeve bolts, a brand name from local company Ramset. They produce a variety of sleeve bolts in varying sizes, materials, and finishes to suit different substrates and fixtures. Chances are, that when shopping for this type of anchor, you’ll be getting a DynaBolt sleeve bolt.

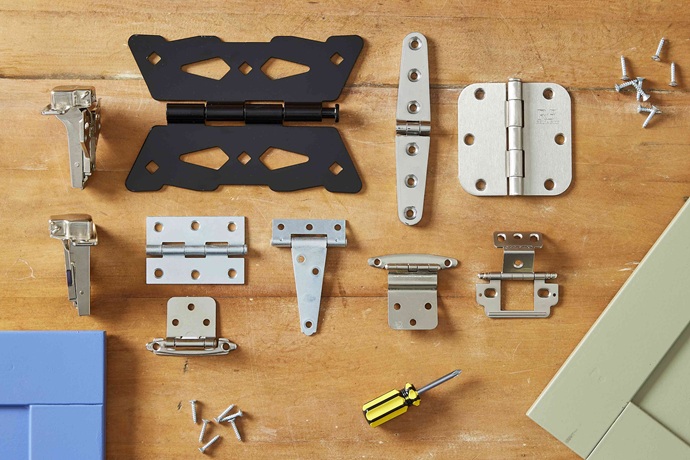

Parts of a Sleeve Bolt

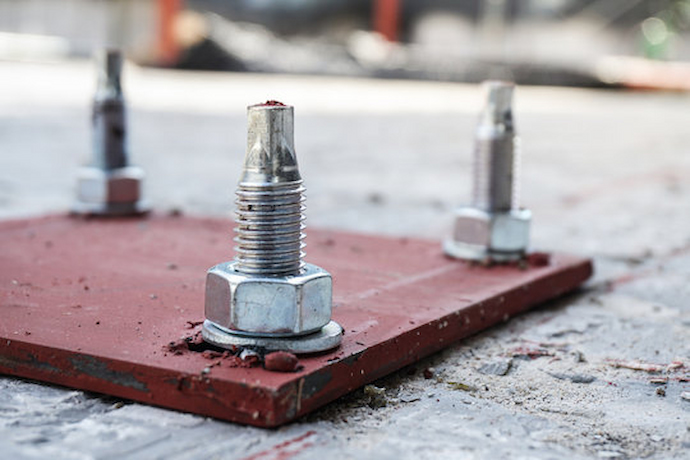

Sleeve bolts come pre-assembled and ready to use. They do however consist of several parts. They get their name from a sleeve that sits around a threaded bolt. The bolt flairs outwards into a cone-shaped base. Most sleeve anchors consist of a hex nut and integrated washer that put pressure on the sleeve as it is tightened. This draws the sleeve downwards and into the substrate and expands when coming into contact with the flared end. This is what locks the anchor firmly into the masonry.

What Makes DynaBolt Sleeve Anchors Special?

Besides being homegrown, DynaBolts are a perfected sleeve anchor. The patented design has the unique ability to ‘pull down’ when tightened, with the sleeve collapsing, meaning a tight and secure anchoring of the fixture. While a DynaBolt sleeve anchor with a hex head is a permanent fastening solution, you can use bolts with other head designs should you want to remove the fixture. This is another advantage of DynaBolt anchors.

Head Designs and Finishes

How heads are designed will determine things like holding strength and the overall look of the sleeve anchor once it’s installed. And whether or not the sleeve and bolt can be removed. Anchors with hex heads and washers stemming from the bolt often have the highest holding power and are meant to be used as permanent fasteners with heavier items fixed to the masonry. Separate hex nuts threaded into headless bolts come close in this respect.

Slightly less strength is exhibited by flush-fitting head designs. Round and countersunk head designs, though, offer more versatility in that they provide the option of removing the bolt, after which the sleeve easily comes off. All you need is a Phillips screwdriver in the right size.

As for appearances, hex nut and hex bolt heads won’t be winning any beauty prizes, but are more about function over form. Round and countersunk heads in sleeve anchors, on the other hand, can be used for decorative purposes. The same applies to overhead hanging from ceilings, with sleeve bolts available in hook, eye, and tie wire bolt head designs. Good for suspended ceilings, chandeliers, or a row of hanging pot plants.

Where are Sleeve Anchors Used?

A DynaBolt sleeve anchor is an ideal fastener for light to medium-duty anchoring. Timber fixtures can easily be fastened to concrete and concrete block. Examples include fixturing timber battens in roofing or fencing. The anchors are also used in hollow or solid brick, for instance when installing wooden window and door frames. Ductwork and piping in air-conditioning is another common application, as is the fixturing of cable trays. Sleeve anchors are preferred in fixturing larger signs and signage in businesses, as well as metal handrails and gates to masonry. Industrials uses include supporting metal racking and shelving, tying down machinery and equipment to concrete floors, and more.

Materials, Sizing and Installation

Different uses and settings require different materials. Austenitic stainless steel (in 316 grade) is perfect for outdoor use, and where there is the potential for exposure to corrosive substances. It also has high tensile strength and low fatigue. Sleeve anchors optioned in carbon or mild steel are good for lighter loads and in controlled settings. Both materials can be treated. Hot-dip galvanised anchors resist rust, so are used outdoors, while zinc-plated variants are used indoors.

As for sizing, sleeve anchors are specified as the width of the bolt and sleeve assembly and by the overall length in millimetres. Widths range from 4.5 to 20mm and lengths from 26 to 157mm. As a rule, holes need to be drilled a bit wider and deeper than the size of the sleeve anchor for the best possible fit and finish.

Installing a sleeve anchor and accompanying timber or metal fixture into masonry is straightforward. Holes are drilled into the masonry to the correct depth and diameter using a hammer drill. Any remaining debris is removed with an air tool or brush. The sleeve anchor is then inserted through the fixture and gently tapped with a hammer until the washer contacts the fixture. The bolt and head are then tightened with a torque wrench or appropriate driver to the recommended torque. The high holding strength is made possible by the expanding sleeve that digs into the substrate material.