Some of you may or may not know what structural metal fabrication is, for those of you who don’t – it is basically the process of shaping, bending or cutting metal to create something. There are so many different ways this can be done, sometimes the metal is also treated to be strengthened. The basic structural metal fabrication process is taking pieces of metal and attaching them together to form a specific size and shape. Of course, this is not an easy job and requires a skilled technician that has experience in taking raw materials and turning them into items that can be sold. When working with metal in order to create something there is no room for error.

Structural metal fabrication is something that most people don’t really think about. It is a part of almost everything we use including our homes and workplaces. We see metal fabrication every day whether it be in footbridges, walkways or staircases making it super important when it comes to our everyday lives. There are many manufacturers, industries, and workplaces that offer structural metal fabrication and work with this process for a variety of different projects. Some of these projects may include building fire escapes, building doors, or even towers. There are a few different ways that this is done using different machinery and techniques to get the desired result. There are three main steps in the process and these steps in no particular order are the following.

Bending

There are a few ways that this is done, the most common one being hammering. Depending on the workplace and its resources, bending metal can either be done manually or with special equipment. The process for bending may vary depending on which result is desired.

Cutting

There are so many ways that you can cut metal. The most common processes for cutting metal include sawing, shearing, and chiseling. There is also a variety of tools that are used in this process such as plasma torches, water jets, or laser cutters. It all really comes down to what result the manufacturer wants to achieve.

Assembly

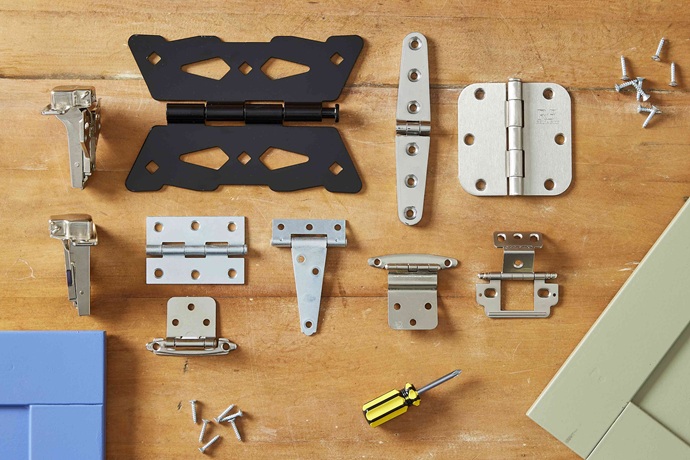

Assembly is where all the metal parts really start to come together to make the final product. This is done by welding each individual piece together. The process of welding implies applying heat to metal to join it to other pieces. While welding is the most popular choice, this can also be done with adhesives or fasteners.

This article has been all about the basics of structural metal fabrication. Hopefully, after reading it you now know just how important it is and how often we use it in our everyday lives. It is an industry that doesn’t seem to be going anywhere anytime soon as there will always be a need for it. If you work in an industry that you think can benefit from structural metal fabrication, or maybe you need something done around your home, you can easily find businesses that offer this service or places that sell the right equipment.