Car engines are complex feats of engineering, consisting of thousands of parts, and hundreds that are moving at the same time. Engines combust a mixture of fuel and air to produce power and turn the wheels. A basic part of the whole process is the camshaft. If you’re rebuilding an engine from scratch, you’ll be well aware of the function of camshafts, and the modifications needed to get the most out of the engine and car for different driving styles. If not, you’re at the right place.

What are Camshafts?

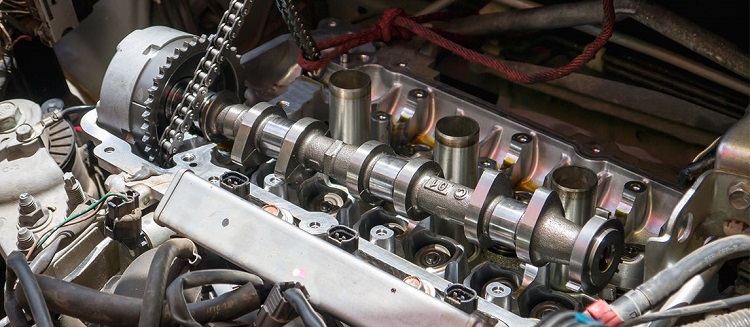

Camshafts are engine parts that actuate the inlet and exhaust valves of the cylinders. They work with other engine parts to precisely control the amount of air and fuel mixture entering the cylinders to efficiently remove the combusted gases out of the cylinder chamber, and prepare for the next cycle. The camshaft is connected to the crankshaft by way of gears, a timing belt or timing chain, and the two work in sync. Camshaft design, particularly the parts in direct contact with the valves – the cam lobes, greatly affects vehicle performance, and the speed at which the valves open and close.

Parts and Materials

Camshafts consist of camshaft journals and cam lobes. The journals are tasked to keep the whole assembly in place as it spins at several thousand RPM in the engine bay. Stemming from the journals are the lobes or cams. These are oval-shaped protrusions that are placed precisely along the shaft. The number of lobes coincides with the number of valves and cylinders in the engine. There will be at least one cam for the inlet valve and one for the exhaust valve in each cylinder. Other parts include cam bearings that shield engine parts during the rotation of the camshaft assembly and cam ends that prevent side-to-side movement, which is the first sign of a misfiring engine. Rotation is provided by a sprocket at the front end, and connected to the crankshaft with a timing belt or chain, or in rare cases, interlocking gears.

In terms of materials, these are engine parts that need to provide extreme rotational and linear forces to act on the valves at high speeds. High tensile metals, mostly cast iron or machined steel billet is chosen, the latter more common in performance camshafts with higher engine speeds.

How do Camshafts Work?

The obvious purpose of camshafts is opening and closing the intake and exhaust valves at the correct time and in correlation with engine speed. With the camshaft indirectly connected to the crankshaft, this also determines the speed at which the pistons complete the intake, compression, power and exhaust cycles. Differences in valve timing, or how long the valves stay open, largely affect how the engine performs and the power it can produce. The crankshaft and camshaft rotate at different speeds. It takes two revolutions of the crankshaft for the camshaft to complete one full engine cycle.

During the intake stroke, the cams push the valves open, drawing air into the cylinder where it will be combusted with fuel. As the crank rotates and pushes the piston upwards into the compression stroke, both valves are closed (the intake valve pushed back by a valve spring), and fuel injectors spray fuel that is ignited with the air by a spark plug. The resulting heat forces the piston down. The connecting rod pushes on the crankshaft journal, and here we have the power stroke. With the piston bottomed out, the exhaust valve opens to remove the exhaust gases. This occurs thousands of times a minute and across all cylinders. Variations in valve timing, or how long the intake and exhaust valves stay open will greatly affect the engine performance. In performance cams, there is a greater overlap between the intake and exhaust cycles than un standard vehicles, but this also has a downside. While providing for more power, it also means the engine will be rough when idling.

Camshaft types

There are 4 common types of camshafts. They differ on the parts that are used to actuate the cam lobes, also known as the lifters. Here we have flat-tappet and roller camshafts, which can be operated hydraulically or mechanically. This leads to hydraulic and solid lifters. Hydraulic roller cams minimise friction, so are able to produce more power. They allow for greater lift and duration, meaning better and more efficient combustion.

Camshaft configurations

Different engines will have a varying number of camshafts, and set differently within the engine. There are two common camshaft configurations – single overhead camshafts or SOHC and double overhead camshafts or DOHC. A single overhead configuration means there is one camshaft operating above the cylinder head. In inline 4 and 6 cylinder engines there is a single camshaft operating all valves, whereas in V6s and V8s there will be two camshafts, or one for each head. Here, valves are actuated by rocker arms, and sprung back by valve springs. SOHC engines are simple designs with fewer parts, but tend to appear in older higher displacement engines. For better efficiency and improved consumption, DOHC engines have two camshafts per cylinder bank. Inline engines have two V engines have four. There is one camshaft for the intake valves and one for the exhaust valves. This allows for more valves, meaning greater airflow and increased power and torque. It also is the basis for variable valve timing, or decreasing or increasing the speed of the valves depending on the RPMs. DOHC cams with variable timing features in many modern performance cars.